The electric vehicle (EV) revolution has brought the automotive industry to the forefront of innovation. While EVs have made significant strides, the technology behind their batteries still has room for improvement. Addressing this need, Stellantis, one of the world’s largest automakers, has partnered with Zeta Energy to develop next-generation lithium-sulfur batteries that promise to be lighter, cheaper, and faster to recharge. This breakthrough could redefine the future of EVs, making them more accessible and sustainable.

Why Lithium-Sulfur Batteries Are the Future

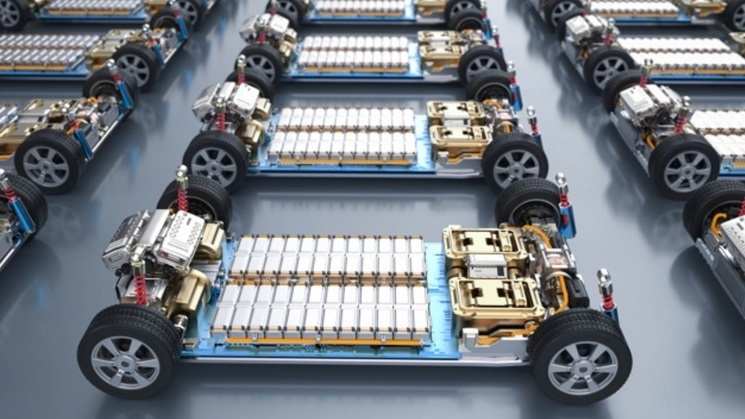

Batteries are the heart of electric cars, dictating everything from cost to performance. Currently, lithium-ion batteries dominate the EV market, but they come with challenges, such as high costs, reliance on rare materials, and lengthy charging times.

Lithium-sulfur technology offers a compelling alternative. These batteries are not only less expensive to produce but also lighter and more efficient, with the potential to significantly enhance EV performance. By 2030, Stellantis and Zeta Energy aim to bring this transformative technology to market.

Key Advantages of Lithium-Sulfur Batteries

1. Cost Savings

One of the most significant benefits of lithium-sulfur batteries is their affordability. Stellantis and Zeta Energy project that these batteries will cost less than half the price per kilowatt-hour (kWh) compared to current lithium-ion batteries. This reduction stems from their reliance on sulfur, a widely available material, rather than expensive and scarce elements like cobalt, nickel, manganese, and graphite.

This shift not only lowers production costs but also mitigates the risk of supply chain disruptions caused by shortages of rare materials.

2. Faster Charging

Lithium-sulfur batteries are expected to improve charging speeds by up to 50%. Faster charging times will make EVs more convenient for drivers, addressing one of the most common concerns about electric vehicles: the time it takes to recharge.

3. Lightweight Design

These batteries will be significantly lighter than their lithium-ion counterparts while maintaining the same energy capacity. The reduced weight translates to better vehicle handling, increased range, and improved overall performance.

4. Environmentally Friendly Production

The production process for lithium-sulfur batteries is notably sustainable. These batteries will use:

- Waste materials

- Methane gas

- Unrefined sulfur

This approach results in lower CO2 emissions compared to conventional battery manufacturing. Moreover, the absence of cobalt and other rare materials further enhances their eco-friendliness.

A Strategic Partnership for Innovation

Stellantis, ranked as the fourth-largest vehicle manufacturer globally, has teamed up with Zeta Energy, a U.S.-based company specializing in high-performance, low-cost rechargeable batteries. Founded in 2014, Zeta Energy is a pioneer in battery innovation, and this collaboration highlights Stellantis’ commitment to advancing EV technology.

What the Partnership Aims to Achieve

- Develop lithium-sulfur batteries that can outperform current lithium-ion batteries in energy efficiency, cost, and sustainability.

- Introduce these batteries to Stellantis electric cars by 2030, marking a significant milestone in EV evolution.

Lithium-Sulfur Batteries vs. Lithium-Ion Batteries

| Feature | Lithium-Sulfur Batteries | Lithium-Ion Batteries |

|---|---|---|

| Cost per kWh | Less than half | High |

| Materials Used | Sulfur, waste materials, methane gas | Cobalt, nickel, manganese, graphite |

| Weight | Lighter | Heavier |

| Charging Time | 50% faster | Slower |

| Environmental Impact | Lower CO2 emissions, no rare materials | Higher environmental cost |

| Supply Chain Risk | Minimal | High, due to reliance on rare metals |

Independence from Global Supply Chains

One of the most critical aspects of lithium-sulfur battery technology is its potential to reduce reliance on global supply chains, particularly those dominated by China. Today, Chinese companies produce over 50% of the world’s EV batteries, giving them a significant edge in the market.

Lithium-sulfur batteries can be manufactured using existing gigafactory technology, with materials sourced locally in Europe or North America. This shift could empower regions like the EU and the U.S. to establish independent supply chains, reducing reliance on imports and bolstering domestic industries.

What This Means for the EV Market

The introduction of lithium-sulfur batteries could address several of the barriers currently hindering EV adoption:

1. Affordability

Lower battery costs mean more affordable EVs, opening the market to a broader range of consumers.

2. Convenience

Faster charging reduces downtime, making EVs more appealing for long-distance travel and daily commutes alike.

3. Environmental Responsibility

Sustainable manufacturing processes align with global efforts to reduce carbon emissions and combat climate change.

4. Greater Autonomy

By using lighter batteries with higher energy capacity, EVs will offer longer ranges, a critical factor for many potential buyers.

The Bigger Picture: EU’s and U.S.’s Vision for EV Dominance

The European Union has pledged €1 billion in subsidies to advance battery manufacturing, signaling its commitment to staying competitive in the global EV market. Similarly, the U.S. is incentivizing domestic battery production to reduce its dependence on foreign suppliers.

Stellantis’ partnership with Zeta Energy aligns perfectly with these goals, as the development of lithium-sulfur batteries represents a major step toward technological independence and environmental sustainability.

Looking Ahead: Stellantis’ Ambitious Goals for 2030

Stellantis plans to integrate lithium-sulfur batteries into its vehicles by 2030, revolutionizing the EV landscape. The automaker’s vision includes not only improving vehicle performance but also enhancing the affordability and sustainability of electric mobility.

As the demand for EVs continues to grow, innovations like these will play a pivotal role in shaping the future of transportation. For consumers, this means more options, better performance, and a smaller carbon footprint.

The partnership between Stellantis and Zeta Energy marks a critical turning point in EV technology. With lithium-sulfur batteries promising 50% faster charging, lower costs, and sustainable production, the future of electric mobility looks brighter than ever.

As we move closer to 2030, the automotive industry is set to undergo a transformative shift, driven by advancements in battery technology. For drivers, this means not only better cars but also a more sustainable and accessible way to embrace electric transportation.

The age of cleaner, faster, and more efficient EVs is on the horizon, and Stellantis is leading the charge.

PEOPLE WHO READ THIS, ALSO READ