The Future of Battery Technology: How Wireless BMS is Revolutionizing Electric Vehicles

The world of electric vehicles (EVs) is advancing at an incredible pace, with innovations emerging to make them lighter, more efficient, and more powerful. One of the most exciting breakthroughs in recent battery technology is the development of wireless Battery Management Systems (BMS), which promise to improve energy density, reduce weight, and simplify manufacturing.

Why Battery Management Systems Matter

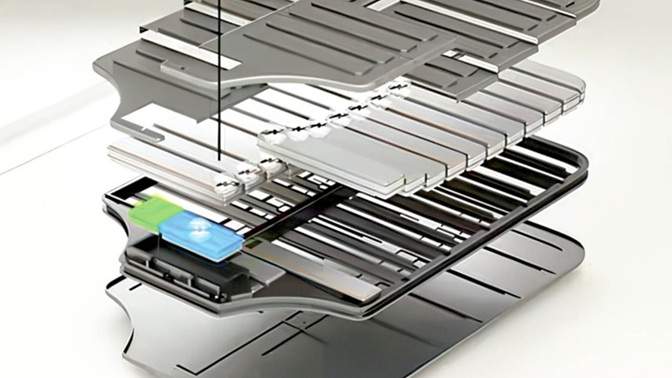

A Battery Management System (BMS) is a crucial component in an EV. It monitors the battery’s electrical and thermal performance, balances the charge between cells, and calculates the battery’s overall health. As automakers push for greater driving range, they need to increase the number of battery cells. However, this also leads to more cables, which adds weight, increases complexity, and raises the risk of failures due to poor connections or breakages.

To address these challenges, manufacturers are moving towards wireless BMS solutions, which eliminate excess wiring and simplify the entire battery system. This shift represents a major leap forward in making EV batteries more reliable, cost-effective, and efficient.

Wireless Battery Management Systems

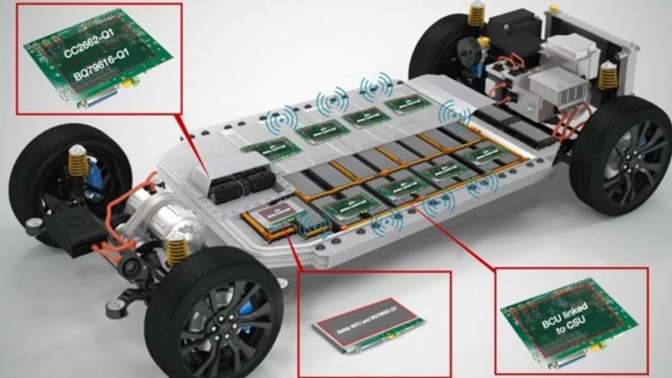

NXP Semiconductors has introduced a revolutionary innovation—the first BMS to use ultra-wideband (UWB) technology. This breakthrough not only enhances the performance of electric and hybrid vehicles but also sets new industry standards for safety, efficiency, and reliability.

Traditionally, BMS relied on complex wiring harnesses to connect individual battery cells. While this method worked, it had some major drawbacks:

- Added Weight: More cables mean a heavier battery pack, which reduces vehicle efficiency.

- Higher Costs: The increased number of components leads to more expensive production and maintenance.

- Failure Risks: Wires can break or develop poor connections, impacting battery performance.

- Complex Assembly: Installing and maintaining wired BMS systems requires extensive labor and time.

To solve these issues, wireless BMS (wBMS) was developed, eliminating physical connections between battery cells and the control unit. Previous wireless solutions relied on narrowband radio frequencies, such as Bluetooth, but they faced interference and connectivity problems.

How Ultra-Wideband (UWB) Technology Changes the Game

NXP’s UWB-based BMS eliminates these weaknesses by offering a more robust, interference-free communication system between the battery cells and the management unit. Here’s why UWB stands out:

- Higher Reliability: Data transmission is stronger and more accurate, ensuring precise battery monitoring.

- No Interference: Unlike Bluetooth, UWB avoids connectivity issues that can compromise system performance.

- Better Energy Density: Eliminating excess wiring allows for more battery materials, increasing overall capacity.

- Simpler Manufacturing: With fewer components, assembling an EV battery becomes easier and more cost-effective.

Inside the Trimension UWB and FlexCom BMS Technology

The Trimension UWB system, part of NXP’s FlexCom chipset, is designed to support both wired and wireless BMS configurations. This gives automakers the flexibility to transition gradually towards fully wireless systems.

According to Naomi Smit, Vice President and General Manager of Battery Management Systems at NXP, “Our wireless BMS system is the first in the industry to include UWB technology, offering manufacturers the most advanced technology to power the electric vehicles of tomorrow.”

The FlexCom chipset includes a battery junction box chip, which provides precise voltage and current measurements, ensuring optimal battery performance and safety. The common software architecture and security libraries make integration seamless, allowing automakers to implement this new technology with minimal adjustments.

What This Means for the Future of EVs

The introduction of UWB-based wireless BMS is a massive step forward for the EV industry. As this technology becomes more widely adopted, we can expect several key benefits:

- Lighter Vehicles: Less wiring means reduced weight, improving efficiency and range.

- Increased Safety: Fewer physical connections lower the risk of electrical failures.

- Lower Manufacturing Costs: Simplified battery assembly leads to reduced production expenses.

- Better Performance: Enhanced energy density and real-time monitoring improve overall battery lifespan and reliability.

NXP plans to make the Trimension UWB system available for evaluation and development by the second half of 2025. If widely adopted, wireless BMS could become the new industry standard, leading to a new generation of lighter, safer, and more efficient electric vehicles.

Battery technology is evolving rapidly, and wireless BMS is one of the most promising advancements in the EV space. By eliminating cumbersome wiring and introducing UWB technology, automakers can build vehicles that are more reliable, cost-effective, and environmentally friendly.

The future of electric vehicles is not just about bigger batteries—it’s about smarter, more efficient systems that push the limits of innovation. With companies like NXP leading the way, we are moving closer to a world where EVs are lighter, safer, and more accessible than ever before.

PEOPLE WHO READ THIS, ALSO READ